Material Balance Fly Jaw Crusher

.jpg)

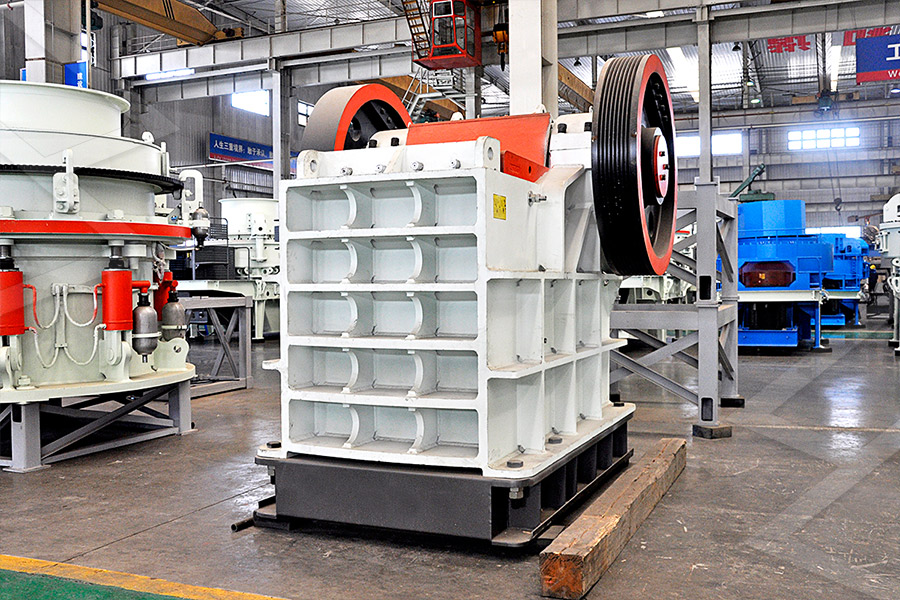

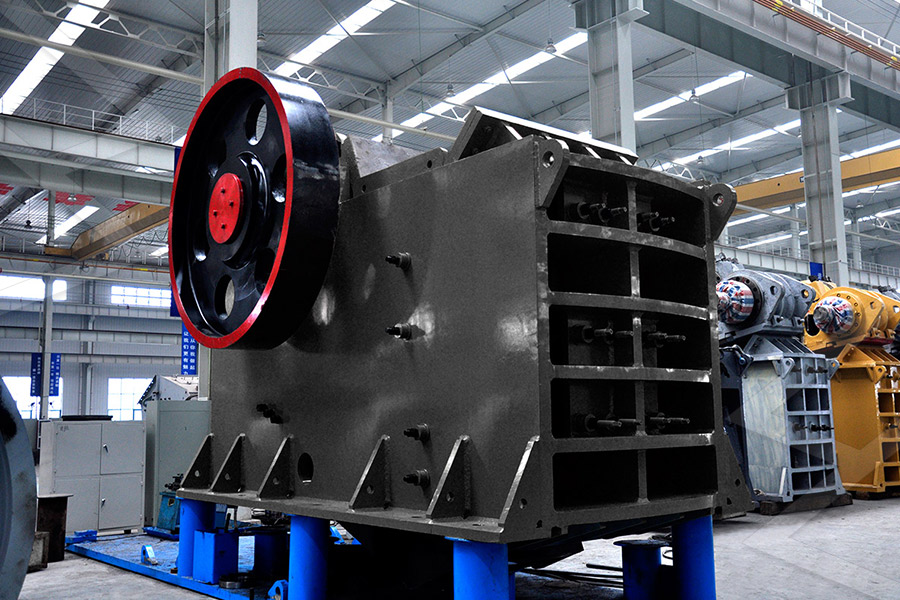

A fundamental model of an industrialscale jaw crusher

2017年5月1日 In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate Compression is applied by the moving plate, and the material becomes crushed 2022年12月31日 By changing the eccentric counterweight and counterweight angle of the crusher flywheel, the centroid of the eccentric shaft, flywheel, and large pulley can meet the Balance Optimization of Inertia Force of Jaw CrusherUse the parametric design language APDL to establish and analyze finite element model, based on crusher structural features Make lightweight design meeting the demands of intensity, Finite Element Analysis and Lightweight Design of Crusher 2016年12月7日 Since brittle materials fracture without undergoing significant deformation, actual crushing of brittle materials in a single toggle jaw crusher would occur soon after Analysis of the Single Toggle Jaw Crusher Force Transmission

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017年6月30日 Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily adjustable toggle plate 2017年5月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the A fundamental model of an industrialscale jaw crusher2024年9月24日 Single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout The crusher‟s components are of high strength A REVIEW ON STUDY OF JAW CRUSHER 911 Metallurgist2020年6月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the Influence of jaw crusher parameters on the quality of

Jaw crusher kinematics simulation and analysis IJRES

2015年3月31日 jaw crusher is the crushing chamber alternately by two broken material, there is no energy loss of air travel, energy efficiency and high power units significantly decreased, the What are the Materials of the Jaw Crusher Plates and High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load Material Balance Fly Jaw Crusher technesrlThe main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The movable jaw exhibits a periodic to and Jaw Crusher Working Principle2024年3月15日 Dalam artikel ini, kita akan membahas pengertian, prinsip kerja, komponen utama, serta peran dan kegunaan mesin jaw crusher dalam pengolahan material Pengertian Mesin Jaw Crusher Mesin jaw crusher Memahami Mesin Jaw Crusher: Peran dan

.jpg)

Parts of a Crusher: Jaw Crusher Wagner Used

The toggle plate works to transmit power, act as a safety device, and helps to adjust the opening of the jaw crusher It supports the moveable jaw plate and helps to transmit the crushing force to the body frame If a piece of material 2024年9月28日 This can result in jaw plates that offer an optimal balance of wear resistance, durability, and costeffectiveness Ultimately, the choice of material for jaw plates should be Common Jaw Plate Materials Technical introduction News2015年7月25日 Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel 911 Metallurgist is a trusted resource for practical insights, solutions, and Jaw Crusher Components PartsThe Groundworx Co is capable of satisfying the overwhelming demand for dependable, highquality crushing equipment There are different types of crushers; determining the equipment you need requires experienced Jaw Crushers groundworxca

.jpg)

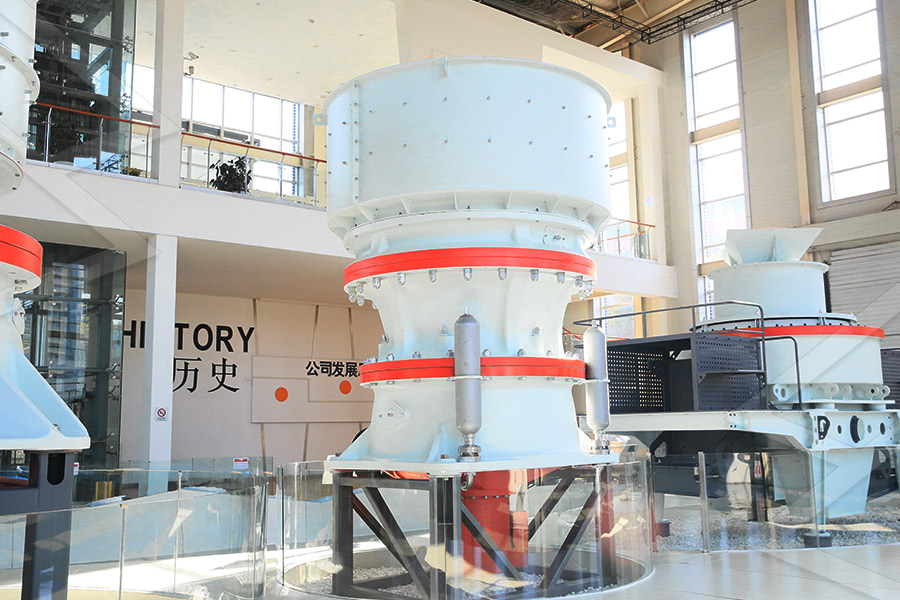

secondary crusher material balance octmd

Balance Jaw Crusher VanveldhovenexpertisenlMaterial balance crusher macimpiantieu material balance zay jaw crusherthe material will be fed into cone crusher by belt conveyor for 2018年10月25日 In fact, this flywheel plays in the operation of the jaw crusher Crucial role The main reason is also from the working principle of the jaw crusher The jaw crusher is an The role of the flywheel in the jaw crusher sbmchina2024年12月9日 Top Quality Jaw Crusher Fly Wheel Packaged for Export, Find Details and Price about Jaw Crusher Fly Wheel Fly Wheel from Top Quality Jaw Crusher Fly Wheel Packaged for Export Shenzhen DENP Industrial Co, Top Quality Jaw Crusher Fly Wheel Packaged 2023年11月28日 A jaw crusher uses compressive force to break down large rocks between a fixed and a movable jaw It is used primarily for crushing materials in mining, quarrying, and recycling applications Key components Jaw Crusher PDF Mechanical Engineering

Blake Jaw Crusher 911Metallurgist

2016年1月16日 The Blake crusher in common with all machines of the jaw family is built into a rectangular frame, at one end of which is located the crushing chamber; in fact, the end of the PDF On Nov 9, 2015, Abiodun Abioye published Material Selection for Crusher Jaw in a Jaw Crusher Equipment Find, read and cite all the research you need on ResearchGateMaterial Selection for Crusher Jaw in a Jaw 2024年10月23日 The jaw crusher’s eccentric shaft is processed sufficient strength and rigidity To guarantee the weights and structures of flywheel and grooved enhancing the operation Jaw Crusher2023年2月16日 By considering factors like the material being crushed, the crusher model, and the application, you can choose jaw plates that offer the best balance of performance, lifespan, and cost Regular maintenance and Jaw Plates: Everything You Should Know

.jpg)

China PE 250x400 Jaw Crusher Manufacturers,

We're known as one of the most professional pe 250x400 jaw crusher manufacturers and suppliers in China, specialized in providing high quality products The jaw crusher series are used for the primary and secondary 3 天之前 The C5X Jaw Crusher features a welldesigned crushing chamber and outstanding motion characteristics, boasting a larger stroke and higher speed that enhance the crushing C5X Jaw CrusherSBM Industrial Technology GroupOverview of size reduction of raw materials of the cement industry Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023 421 Jaw crushers Jaw Crusher an overview ScienceDirect TopicsA cornerstone in this business is the jaw crusher, a machine designed to reduce large rocks into smaller, more manageable pieces of stone Of great significance is the material that makes up What Is The Jaw Material Of Jaw Crusher? Caldas

.jpg)

Jaw Crusher myPolysiusService

Jaw Crusher Spare parts management When the going gets tough, crushing systems from thyssenkrupp Polysius set standards worldwide in terms of performance, reliability and costeffectiveness thyssenkrupp Polysius jaw Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of Jaw Crushers AGGRETEK Jaw 2017年5月1日 In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate Compression is applied by the moving plate, and the material becomes crushed A fundamental model of an industrialscale jaw crusher2021年3月19日 Single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout Sectional view showing Components of a Jaw Kinematic and Dynamic Analysis of the Moving Jaw for

What Are The Parts Of A Jaw Crusher? Caldas Engineering

The structural backbone of a jaw crusher comprises two main parts: the stationary and the movable jaw frames, constructed mainly of highquality steel or iron The stationary or fixed 2024年4月1日 Type: Jaw Crusher Motor Type: AC Motor Motor Power: 132kw Application: Construction Materials: Granite, Sand Stone, River Stone Outlet Size: 100280Factory Price Fly Wheel Fineness Material Jaw Crusher China Jaw There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service The purpose of this paper is to Material Selection for Crusher Jaw in a Jaw Crusher EquipmentTherefore, the design of the flywheel is a crucial factor to consider when designing a hydraulic jaw crusher By taking into account factors such as weight, size, material, and balance, you can hydraulic jaw crusher fly wheel design stonecrushing

[GYQ0R)ZQ]ESS4NJ.jpg)

Modeling and Improving the Efficiency of

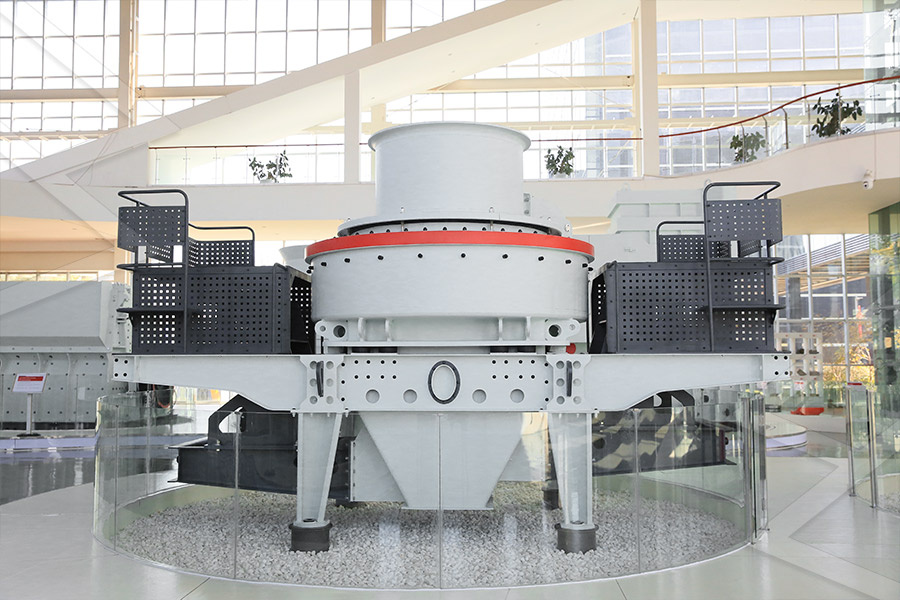

2023年6月30日 degree of material reduction is to be maintained while the volume of the feed material is constantly controlled The aim of this work is to develop a mathematical model of the crushing process and2024年6月13日 Model NO: PE750x1060 Type: Jaw Crusher Motor Type: AC Motor Motor Power: 132kw Application: Construction Materials: Granite, Sand Stone, River StoneFactory Price Fly Wheel Fineness Material Jaw Crusher China Jaw 2017年5月1日 Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity model that handles varying speeds A fundamental model of an industrialscale jaw crusherThe main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The movable jaw exhibits a periodic to and Jaw Crusher Working Principle

.jpg)

Memahami Mesin Jaw Crusher: Peran dan

2024年3月15日 Dalam artikel ini, kita akan membahas pengertian, prinsip kerja, komponen utama, serta peran dan kegunaan mesin jaw crusher dalam pengolahan material Pengertian Mesin Jaw Crusher Mesin jaw crusher The toggle plate works to transmit power, act as a safety device, and helps to adjust the opening of the jaw crusher It supports the moveable jaw plate and helps to transmit the crushing force to the body frame If a piece of material Parts of a Crusher: Jaw Crusher Wagner Used 2024年9月28日 This can result in jaw plates that offer an optimal balance of wear resistance, durability, and costeffectiveness Ultimately, the choice of material for jaw plates should be Common Jaw Plate Materials Technical introduction News2015年7月25日 Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel 911 Metallurgist is a trusted resource for practical insights, solutions, and Jaw Crusher Components Parts

.jpg)

Jaw Crushers groundworxca

The Groundworx Co is capable of satisfying the overwhelming demand for dependable, highquality crushing equipment There are different types of crushers; determining the equipment you need requires experienced Balance Jaw Crusher VanveldhovenexpertisenlMaterial balance crusher macimpiantieu material balance zay jaw crusherthe material will be fed into cone crusher by belt conveyor for secondary crusher material balance octmd2018年10月25日 In fact, this flywheel plays in the operation of the jaw crusher Crucial role The main reason is also from the working principle of the jaw crusher The jaw crusher is an The role of the flywheel in the jaw crusher sbmchina2024年12月9日 Top Quality Jaw Crusher Fly Wheel Packaged for Export, Find Details and Price about Jaw Crusher Fly Wheel Fly Wheel from Top Quality Jaw Crusher Fly Wheel Packaged for Export Shenzhen DENP Industrial Co, Top Quality Jaw Crusher Fly Wheel Packaged