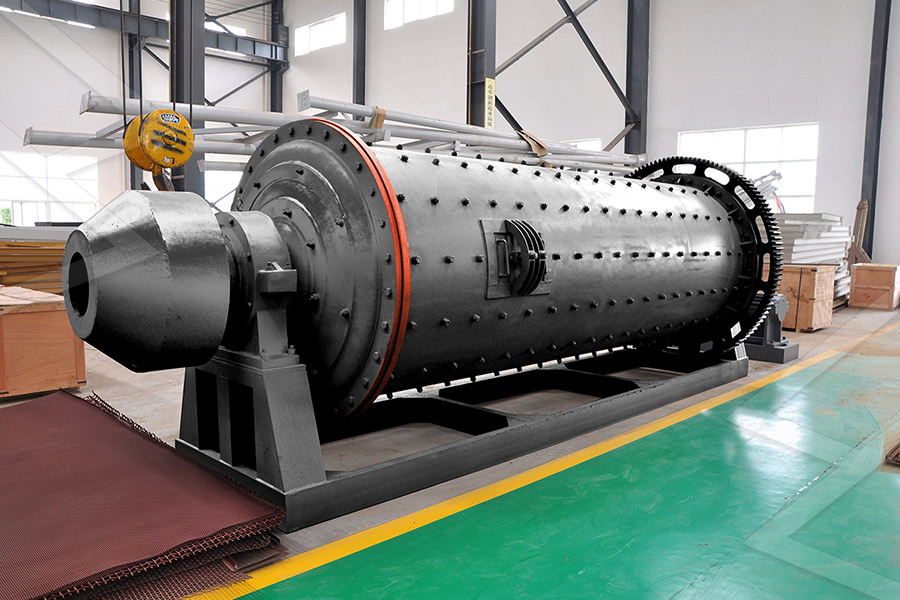

What Is The Feed Size For Ball Mill

.jpg)

What Is The Feed And Product Size Of A Ball Mill? 4 Key

The feed size for a ball mill typically ranges up to 15 mm for mills with diameters between 200300 mm This size limitation is crucial as it ensures that the material can be effectively 2024年6月21日 In summary, in actual production, each beneficiation plant should find the most suitable mill feeding particle size based on the scale of the beneficiation plant and the How to choose the feed size of ball mill is very important2015年6月19日 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The Ball Mill Design/Power CalculationThe feed size for a ball mill generally falls within the range of 12 inches (2550 mm) for large mills, but this can vary depending on the mill design and the material being processed For what is the feed size for ball mill? zenithmineral

.jpg)

Calculate Ball Mill Ball Size for Optimum Grinding

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA 2023年3月6日 The feed size for a ball mill varies depending on the size of the machine and the material being processed In general, the feed size for a ball mill is usually less than 20mm orwhat is the feed size for ball mill? LinkedInThe ideal feed size for coal ball mills is typically between 05 and 10 millimeters This size range allows for efficient grinding while minimizing wear and tear on the mill If the feed size is too large, it can cause the mill to overload and Feed Size of Coal Ball Mill in Power Plantonline live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross powerball mill calculations, grinding media filling degree, ball size, mill

Effect of ball and feed particle size distribution on the milling

2018年6月1日 A number of researchers (Deniz, 2012; Bwalya et al, 2014; Petrakis et al, 2016) carried out studies about the effect of feed particle size and grinding media size on the 2021年1月12日 Mill Weight Power Top Size Figure 4: Feed Top Size vs SAG Mill Performance 5000 5500 6000 6500 7000 7500 8000 8500 9000 9500 10000 13:00 14:00 15:00 16:00 17:00 I203 I204 INTRODUCTION SMC Testing2024年7月17日 what is a ball mill used for? A ball mill is a type of grinder used to grind and blend materials for use in various industries and applications It works on the principle of impact and attrition: size reduction is done by what is a ball mill used for2017年2月13日 Right hand mill is standard This should show the ball mill (feed, discharge and position of drive); Unit Flotation Cell or a Mineral Jig, if in circuit, and classifier of the various sizes of Marcy Ball Mills are given in Ball Mills 911Metallurgist

THE OPTIMAL BALL DIAMETER IN A MILL 911

2024年9月24日 The ball size in a mill has a significant influence on the mill throughput, power consumption and ground material size (Austin et al, 1976; Fuerstenau et al, 1999; For a DOI: 101016/JMINENG2019 Corpus ID: ; Tailoring ball mill feed size distribution for the production of a sizegraded product @article{Chimwani2019TailoringBM, Tailoring ball mill feed size distribution for the production of a size Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear Ball Mill an overview ScienceDirect TopicsThe ball ratio for ball milling typically refers to the optimal filling level of the mill with balls to consider other factors such as the size, density, and number of balls, the nature of the grinding material, the feed rate, and the rotation What is the Ball Ratio for Ball Milling? (3035

Tailoring ball mill feed size distribution for the production of a size

2019年9月1日 The prepared narrow feed size classes; −850 + 600, −600 + 425 and −425 + 300 µm, were each ground using single ball sizes of 20 and 30 mm steel balls The feed material 4 天之前 The balls which could be of different diameters occupy 30 50% of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to Ball Mill Principle, Construction, Working, and 2024年10月13日 Application: Consider the type of materials to be processed and the desired particle size Different ball mills may be more suitable for certain materials and particle size Technical specifications and selection guide for ball mills2015年4月24日 9 Feed rate:With a high feed rate,less size reduction is effected since in this case the material is in the mill for a shorter time Properties of the feed material:With a hard Ball mill PPT SlideShare

.jpg)

What is a Ball Mill Explained: InDepth

2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell 2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide BALL MILLS Ball mill optimisation Holzinger ConsultingBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and Ball Mill (Ball Mills Explained) saVRee where Ω E is the energycorrected ball wear rate, g per kWh, d R is the diameter of the largest balls in the mill (the recharge size), mm, K d E is the linear wear rate of balls, µm per kWh t Ball Mill an overview ScienceDirect Topics

How can one select ball size in ball milling and

2015年1月31日 Bigger balls helps in size reduction if the feed particles are bigger in size like chunks If the powder is feed for milling then smaller ball size is preferred for homogeneous mixing and milling 2024年4月28日 had decreased for the 2 mm +14 mm monosize feed compared to the bigger 4 mm +28 mm monosize feed This therefore shows that should the material feed size The Effect of Ball Size Diameter on Milling Performance2024年6月21日 We all know that ball mills are one of the most important equipment in mineral processing operations The normal operation of ball mills has a significant impact on the How to choose the feed size of ball mill is very importantJanuary 2007, two complete grinding circuit surveys were performed followed by a SAG mill crash stop and grindout After stopping the mill, a SAG mill feed sample was also collected Comparison of SAG mill feed size

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 When grinding materials with small feed particles, such as sand no 2 slag and coarse fly ash, the cylinder of the mill can be separated into a single silo grinding,and the Request PDF On Aug 1, 2019, Ngonidzashe Chimwani and others published Tailoring ball mill feed size distribution for the production of a sizegraded product Find, read and cite all the Tailoring ball mill feed size distribution for the production of a size 2013年7月15日 The sample was received crushed appropriately for the ball mill test Ball Mill Grindability Test was conducted by standard practice using 100mesh (150 pm) closing screens Bond Work Index FormulaEquation2016年10月23日 The size of feed and tonnage rates are also important factors Speed of scoop lip is important Listed below for your convenience is a table showing critical speeds for Ball Mill Feeders 911Metallurgist

Calculate Top Ball Size of Grinding Media FRED

2015年9月6日 Although it was developed nearly 50 years ago, Bond‘s method is still useful for calculating necessary mill sizes and power consumption for ball and rod mills This paper discusses the basic development of the Bond 2024年12月12日 Size Limitations While ball mills excel at fine grinding, they may not be ideal for extremely largescale operations where other grinding methods could be more efficient 5 What Is a Ball Mill? Understanding How It Works, Its Types, 2023年3月24日 As a rule of thumb, the grinding balls should be approximately 3 x larger than the largest sample particle In addition to the instrument settings and the ball size, the filling Guidelines for sample amount and ball charge Content2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and (PDF) Grinding in Ball Mills: Modeling and Process Control

Supervisory expert control for ball mill grinding circuits

2008年4月1日 A ball mill consists of a cylindrical shell rotated about its axis by a motor Heavy metallic balls called grinding media are loaded into the cylinder The coarse ore (usually from 2018年6月1日 A number of researchers (Deniz, 2012; Bwalya et al, 2014; Petrakis et al, 2016) carried out studies about the effect of feed particle size and grinding media size on the Effect of ball and feed particle size distribution on the milling 2021年1月12日 Mill Weight Power Top Size Figure 4: Feed Top Size vs SAG Mill Performance 5000 5500 6000 6500 7000 7500 8000 8500 9000 9500 10000 13:00 14:00 15:00 16:00 17:00 I203 I204 INTRODUCTION SMC Testing2024年7月17日 what is a ball mill used for? A ball mill is a type of grinder used to grind and blend materials for use in various industries and applications It works on the principle of impact and attrition: size reduction is done by what is a ball mill used for

Ball Mills 911Metallurgist

2017年2月13日 Right hand mill is standard This should show the ball mill (feed, discharge and position of drive); Unit Flotation Cell or a Mineral Jig, if in circuit, and classifier of the various sizes of Marcy Ball Mills are given in 2024年9月24日 The ball size in a mill has a significant influence on the mill throughput, power consumption and ground material size (Austin et al, 1976; Fuerstenau et al, 1999; For a THE OPTIMAL BALL DIAMETER IN A MILL 911 DOI: 101016/JMINENG2019 Corpus ID: ; Tailoring ball mill feed size distribution for the production of a sizegraded product @article{Chimwani2019TailoringBM, Tailoring ball mill feed size distribution for the production of a size Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear Ball Mill an overview ScienceDirect Topics

What is the Ball Ratio for Ball Milling? (3035

The ball ratio for ball milling typically refers to the optimal filling level of the mill with balls to consider other factors such as the size, density, and number of balls, the nature of the grinding material, the feed rate, and the rotation 2019年9月1日 The prepared narrow feed size classes; −850 + 600, −600 + 425 and −425 + 300 µm, were each ground using single ball sizes of 20 and 30 mm steel balls The feed material Tailoring ball mill feed size distribution for the production of a size 4 天之前 The balls which could be of different diameters occupy 30 50% of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to Ball Mill Principle, Construction, Working, and